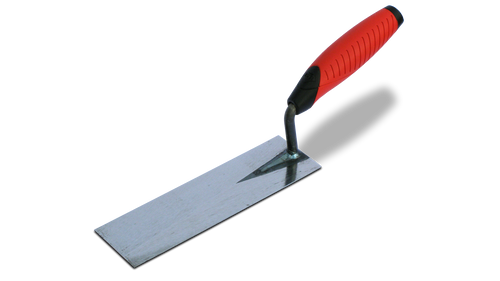

Product Description

The brick trowel is, without a doubt, an essential tool for construction professionals. It is used mainly for mixing materials and to apply them on a trowel or directly onto the surface.

RUBIFLEX PFP33 brick trowels with bi-material handles are the result of constant advanced technological research work to obtain a product of high quality and durability. By applying the latest technologies RUBI can offer building professionals a range of brick trowels with the best guarantees of quality.

RUBI also has the exclusive line with RUBIFLEX® bi-material ergonomic handles, a design that provides great shock resistance. The elastic coating of RUBIFLEX® handles reduces slippage and provides maximum grip.

The plates on RUBI PFP33 brick trowels receive a specific heat treatment that improves their flexibility and reduces wear. In the same way as the shank of the plate, to increase its hardness and rigidity and make RUBI brick towels an extremely light tool with excellent strength and easy to use.

The fibres of the plate have been oriented lengthwise during rolling.

Due to modern manufacturing processes, RUBI brick trowels guarantee complete uniformity of all items, perfect flatness and great strength as well as guarding against corrosion of the plates. In addition, thanks to the use of the exclusive technique of melting at forging temperature they also offer a lifetime guarantee against breakage at the joint between the shank of the handle and the base of the plate.

The attachment between the handle and the shank on the RUBIFLEX PFP33 brick trowels with bi-material handles is solid and non-detachable.

RUBI is present in more than 120 countries through our network of sales offices and authorized distributors. For this reason, we make it easy for users around the world to find our tools and spare parts. Contact us at "Discover RUBI" or any of our social networks for information on where to find a dealer, we will gladly help.

Features

- Ergonomic RUBIFLEX handle

- Solid and unbreakable fixation between handle and spike.

- Fusion technique at forging temperature. Lifetime warranty against breakage.

- Perfect flatness of all the plate.

- Good protection against sheet corrosion

- Fibers oriented longitudinally during rolling.

- Specific heat treatment in:

- Plate to improve flexibility and prevent wear.

- Rod to increase hardness and rigidity

- Maximum lightness retaining its resistance.

- Total regularity of all the fabrications.