Product Description

- Powerful Function: This variable frequency drive has a 1 or 3 phase input and 3 phase output. Control mode: V/F control and vector control. Frequency setting mode: digital setting, analog setting, serial communication setting, and so on. Various control techniques by both synchronization and non-synchronization dynamically realize fast starting without changing brakes.

- Low-Noise Operation: The CNC variable frequency drive inverter features low noise and low electromagnetic interference through the optimization of PWM control technology and electromagnetic compatibility of the overall design. There is enough space for heat dissipation between electronic components, and the shell adopts porous heat dissipation, which has a longer service life.

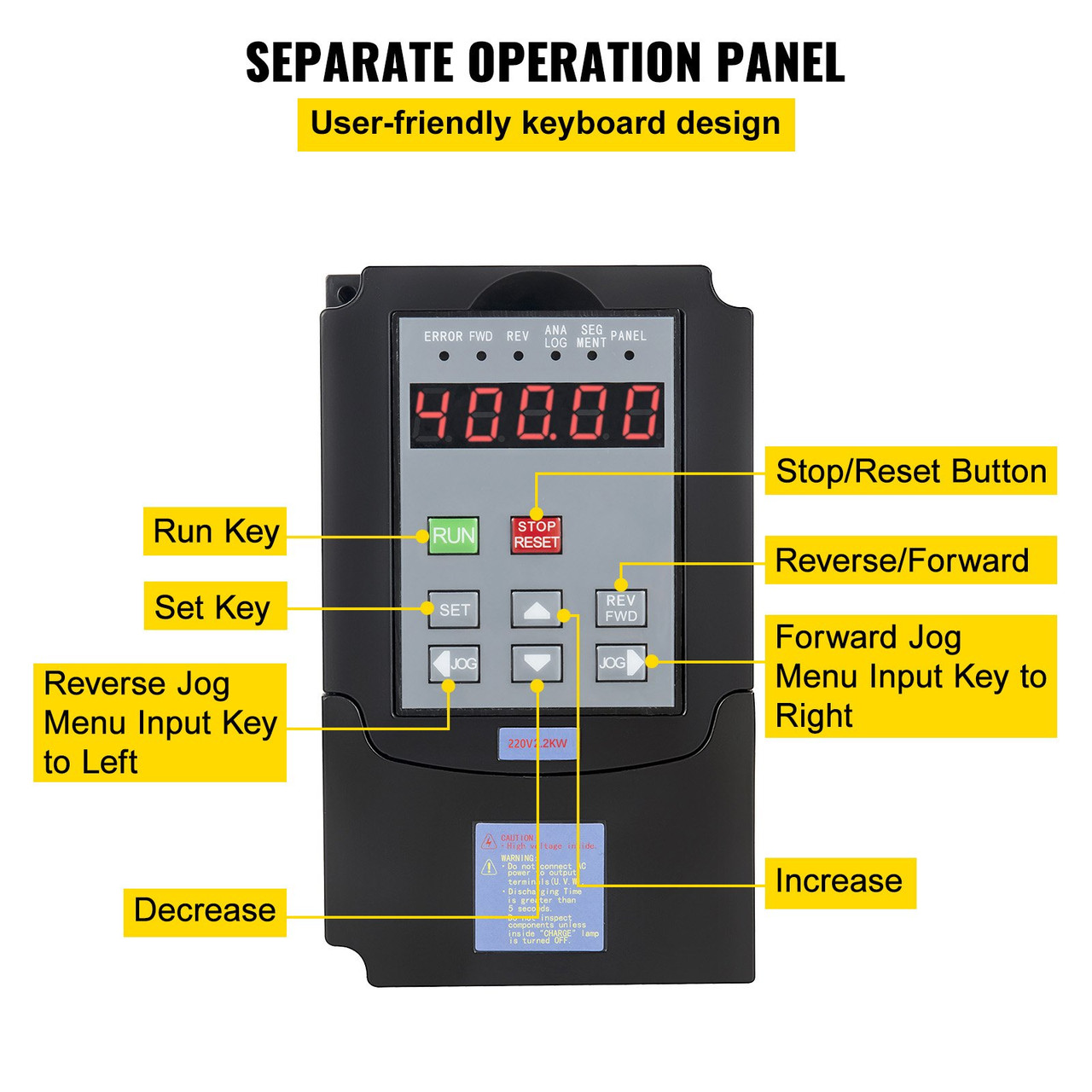

- Smart Digital Display: The VFD adopts a user-friendly keyboard design and reasonable layout, with full-featured clear buttons to achieve quick and easy operation. Also, the large digital display is intuitive and easy to read. The detachable design of the panel is convenient for remote control.

- Multiple Protection: We adopt various protection ways to ensure the stable and reliable operation of the CNC frequency drive inverter, such as overload protection, fuse protection, over-voltage (DC voltage>400V), or under-voltage (DC voltage<200V) protection, restart protection, stall protection, short-circuit protection, and over-heat protection.

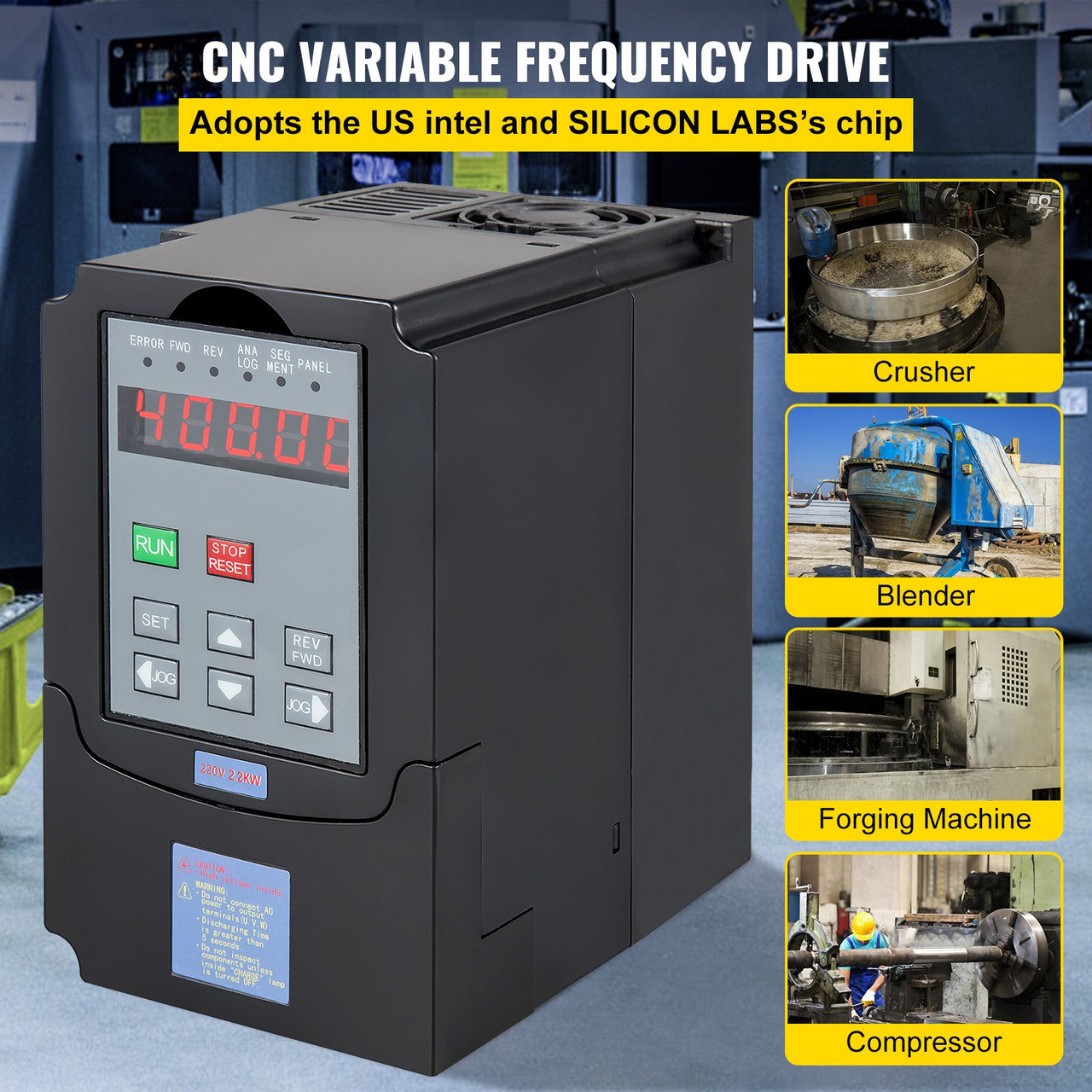

- Versatile Use: The main application area involves a spindle motor, CNC engraving machine, CNC milling machine, CNC machine tool, milling machine, drilling machine, trimming machine, mixer, extruder, slitting machine, rewinder, compressor, ventilator, pump, grinder, conveyor. Speed regulators such as elevators (cannot be used for passenger elevators), centrifuges, etc.